MANUFACTURING

Additive Manufacturing at Scale

Fabric8Labs operates fleets of ECAM printers to serve a diverse product portfolio and customer base. Each print is continuously monitored at the pixel scale, with real-time print algorithms that drive part quality and in-situ part inspection. Every part delivered from our facility has a unique digital fingerprint that provides traceability and verifies compliance to product requirements.

Our service model approach drastically reduces friction to bring next generation products to market. Applications engineers engage directly with your technical teams, and lead product development through qualification and ramp up to high-volume manufacturing.

With production facilities currently located in our San Diego, CA headquarters, our manufacturing footprint will expand globally to support the rapidly growing demand.

3D Imap

Industry 4.0

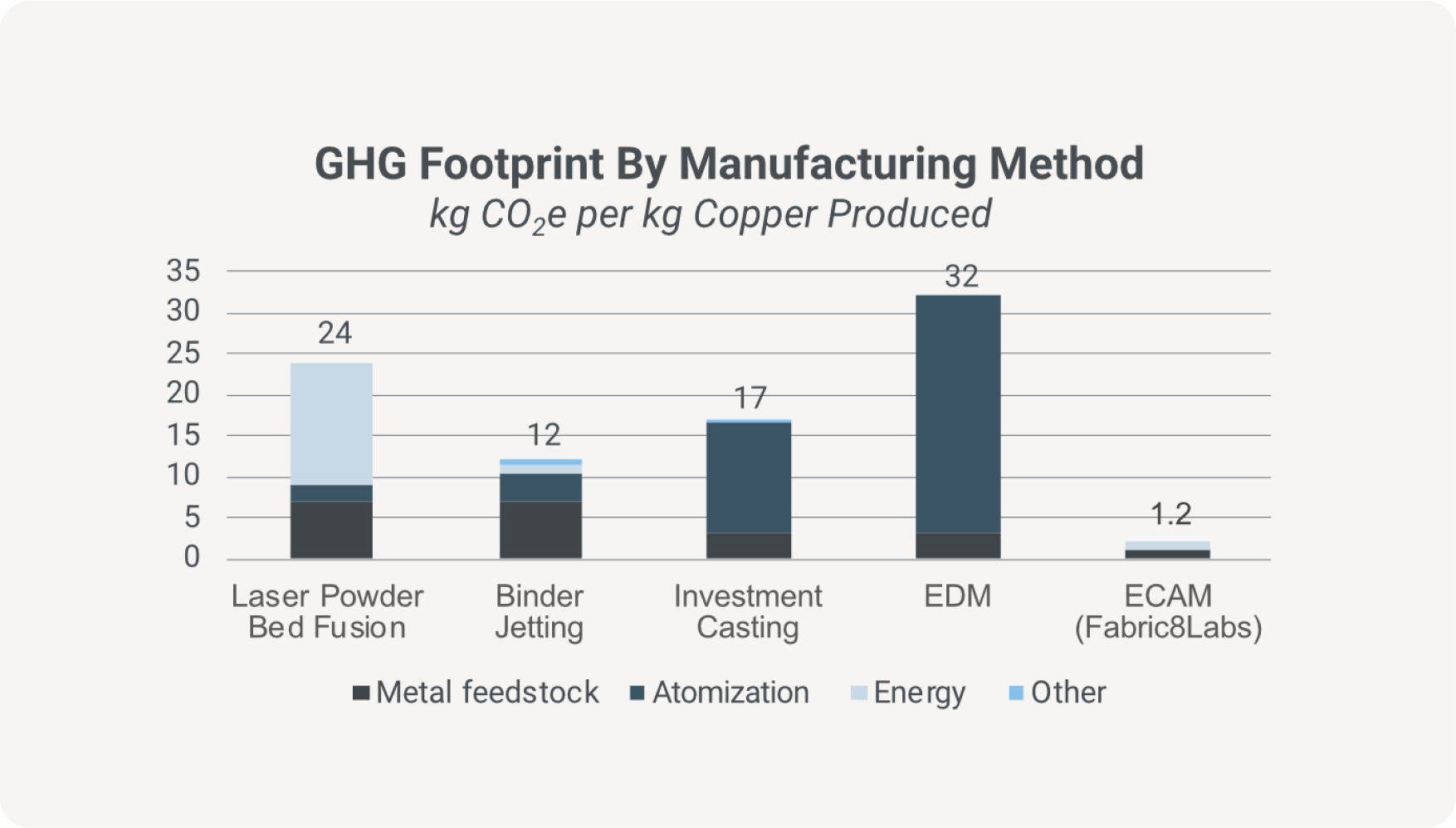

Metal additive manufacturing (AM) is revolutionizing production, but traditional methods can leave a large environmental footprint. Electrochemical Additive Manufacturing (ECAM) offers a breakthrough solution, printing complex metal parts at room temperature, using water-based feedstocks, with significantly less impact on the planet.

- Part quality measured pixel-by-pixel in real time during manufacturing

- 3D Imap recreates the manufactured part as a 3D digital quality record

- Quality specifications are integrated into each printed layer, ensuring no hidden defects

MANUFACTURING AT SCALE

IN-SITU Quality MONITORING

CERTIFICATIONS

DFARS COMPLIANT

ITAR REGISTERED