Electrochemical

Additive

Manufacturing

WHAT IS ECAM TECHNOLOGY?

Ultra-high resolution, massively scalable, advanced metal additive manufacturing.

Electrochemical Additive Manufacturing (ECAM) is a room-temperature 3D metal printing technology that produces complex, dense metal parts without post-processing.

Contrary to most metal AM methods which utilize expensive metal powder feedstocks and high-temperature processes, ECAM utilizes a water-based feedstock composed of widely available and low-cost metal salts. The feedstock is similar to electroplating chemistries used in printed circuit board (PCB) and semiconductor manufacturing.

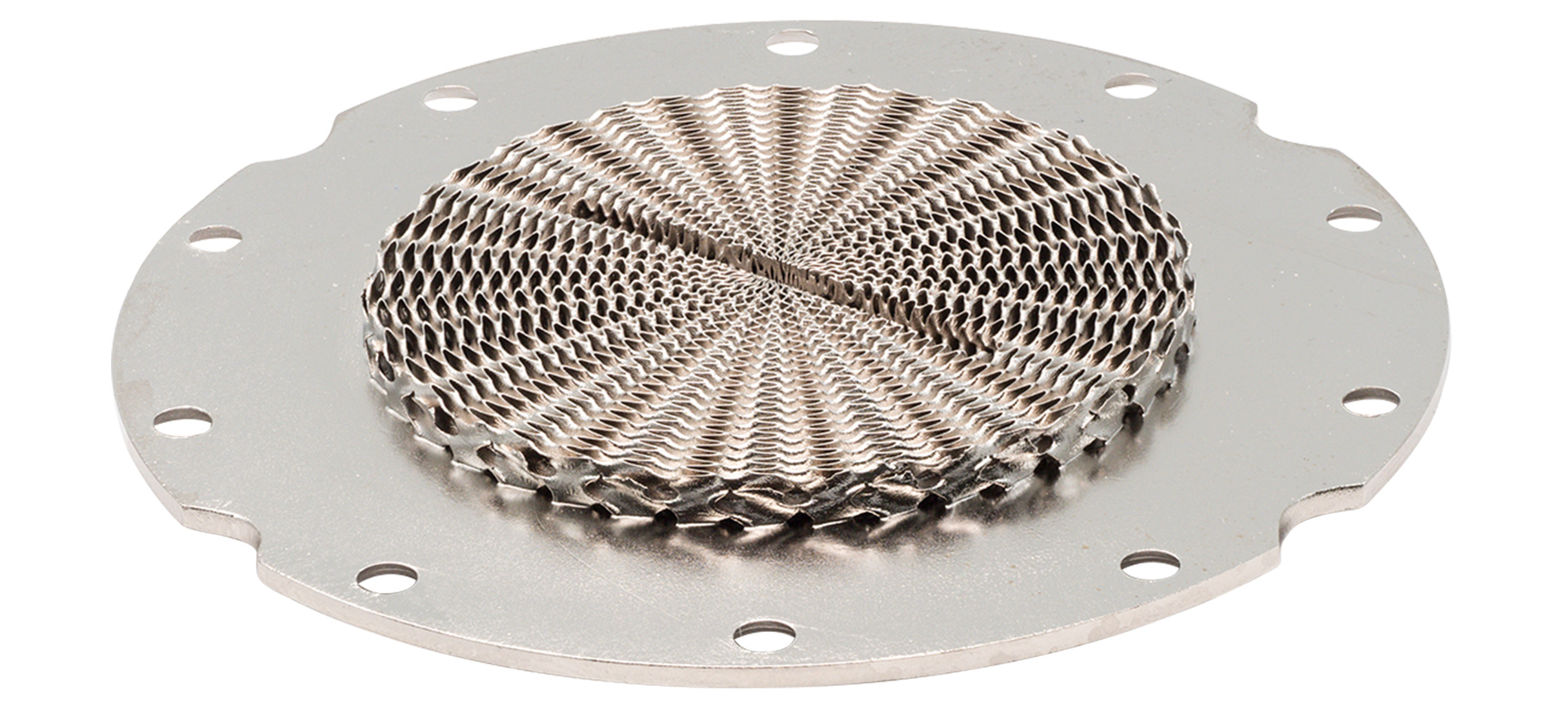

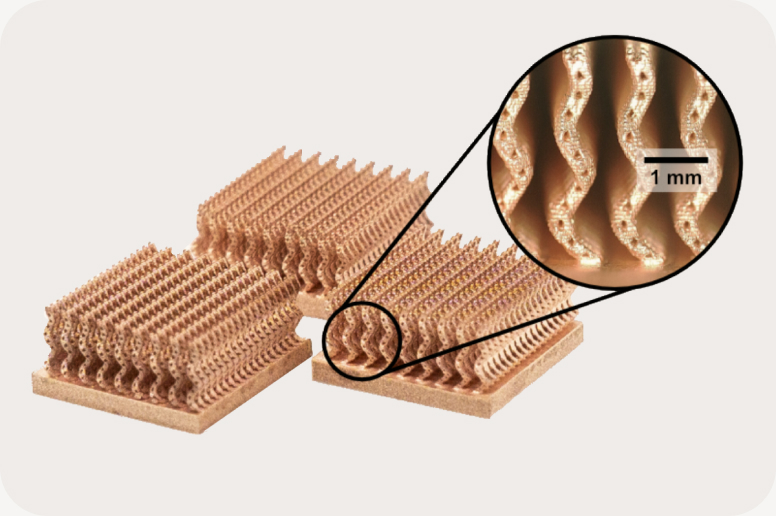

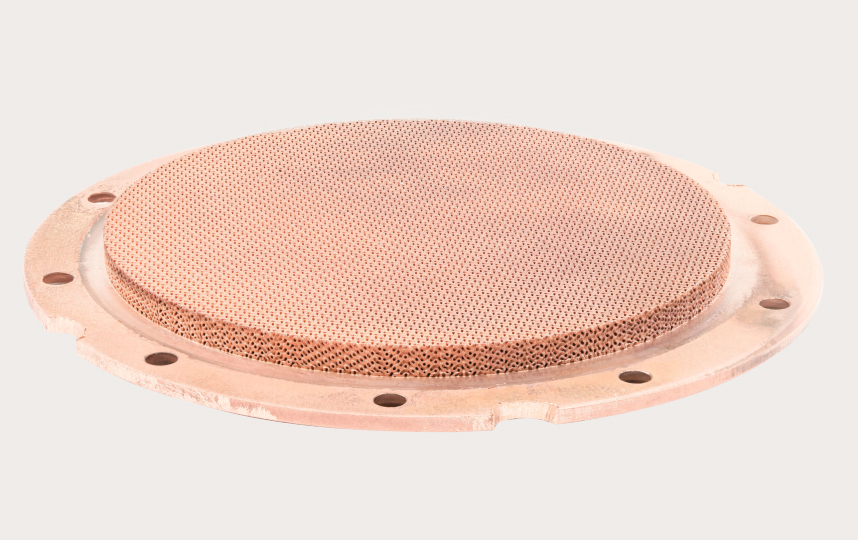

The key innovation enabling the ECAM process is the printhead, a micro-electrode array of millions of individually addressable pixels on the scale of 10s of microns. Utilizing this microelectrode array in conjunction with the metal ion rich feedstock, ECAM builds at the atomic level allowing for micron-scale feature resolution, complex internal features, high-purity materials, low surface roughness, and rapid scalability to support mass manufacturing.

Available materials include any materials that can be electroplated, such as pure copper, copper alloys, nickel, nickel alloys, tungsten alloys, tin, gold, platinum, and palladium. By fabricating parts electrochemically, structurally sound parts are produced directly from the printer that do not require post-processing to achieve their desired material properties.

ECAM ENABLES ADDITIVE MANUFACTURING FOR HIGH PERFORMANCE COMPONENTS

ECAM is an exciting new manufacturing platform that enables additive

manufacturing in high volume, high growth markets such as electronics, wireless

communications and medical devices. End-users select ECAM based on its unique

combination of features and the benefits they provide.

Ultra-high resolution, complex structures

High-precision, 33 micron voxels enable complex features that maximize performance.

Substrate compatibility

Room-temperature processing allows for direct-print on a wide range of materials, such as printed circuit boards, lead-frames, ceramics, metals, and silicon.

High-Purity

ECAM copper is 99.95% pure for optimal thermal and electrical performance.